Cold Weather Operations

How different powertrains behave when the mercury drops

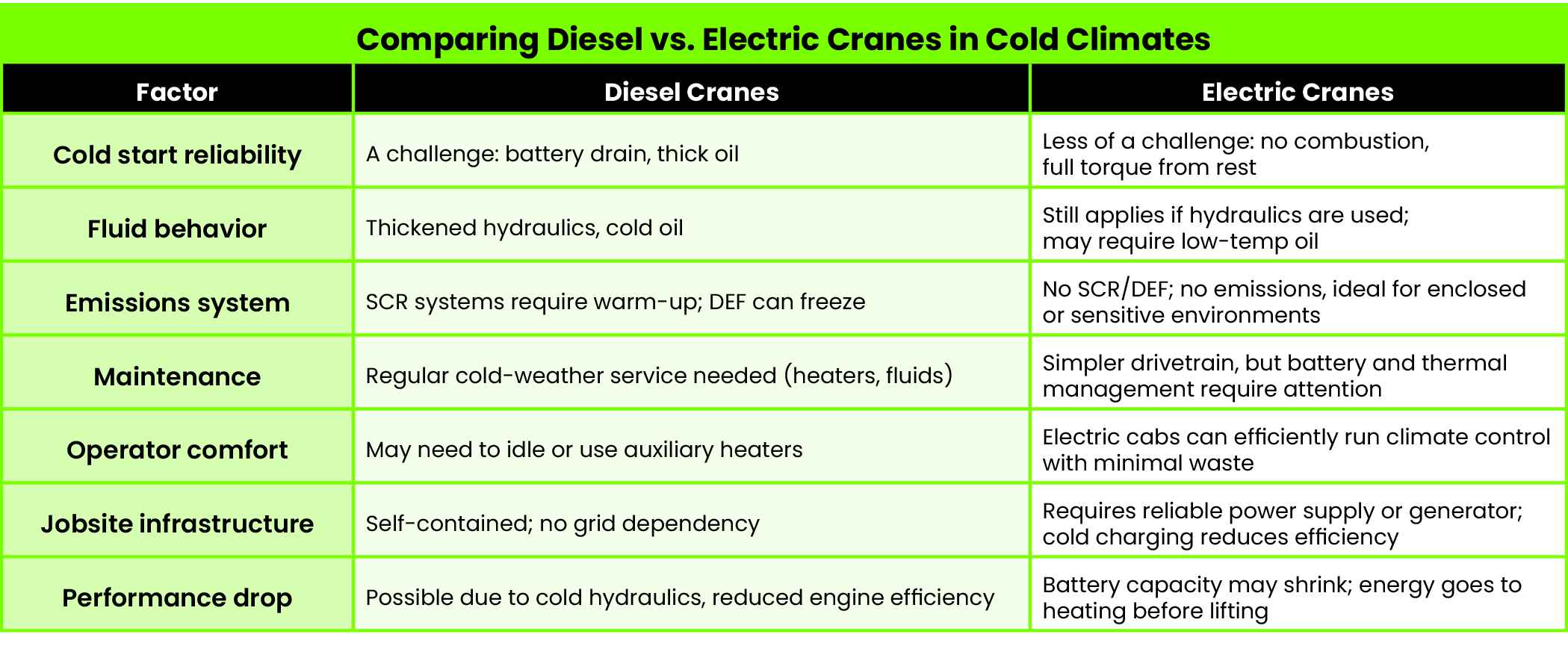

For crane operations in cold climates — from northern U.S. states and Canada in winter to high-altitude builds — temperature is more than an inconvenience. It’s a performance factor, a safety risk and a significant maintenance concern. As the crane industry adopts cleaner, electrified machines, operators must consider the needs of different powertrains in cold weather operations.

Winter Challenges for Diesel Cranes

For diesel-powered cranes, cold weather introduces several complications:

- Cold Starts — Diesel engines become harder to start in freezing temperatures. Battery capacity drops in the cold, and oil viscosity increases, which makes cranking more difficult. Operators may need block heaters, battery warmers and appropriate winter-grade lubricants.

- Hydraulics and Fluids — Hydraulic fluid thickens in low temperatures, slowing down system response. This affects boom extension, winch speed and overall smoothness of operation. Without pre-warming, cold hydraulic fluid can cause sluggish or jerky movement, risking damage to components.

- Exhaust System Issues — For Tier 4 Final SCR systems, diesel fuel and DEF (Diesel Exhaust Fluid) must remain within a proper temperature range. In very cold climates, these fluids can gel or freeze if not properly insulated or heated, preventing correct flow and potentially triggering fault codes or engine derating.

- Metal Fatigue and Brittleness — While modern steels used in crane booms are typically robust, extreme cold can exacerbate brittleness or fatigue risks, especially at welds or joints. Operators must carefully inspect booms, pins and sheaves before lifting in subzero conditions.

- Maintenance — Cold weather increases maintenance demands. Regular checks of batteries, antifreeze, hoses, seals and hydraulic systems are needed. Without careful winterization in advance of cold weather as well, cranes may suffer leaks or frozen lines, leading to unplanned crane downtime during winter months.

Electric Crane Cold Weather Performance

Electric powertrains (either pure battery-electric or hybrid) promise clean operation, zero local emissions and often simpler mechanics, but winter conditions present their own set of trade-offs for these machines:

- Battery Performance Losses — Battery runtime can drop significantly in the cold — potentially down by up to 50% — because of reduced chemical activity, increased internal resistance and higher energy demands for cab heaters and hydraulic systems.

- Hydraulic Efficiency — Many electric machines still use hydraulic actuation for lifting and boom functionality. In low temperatures, hydraulic inefficiencies (such as sluggishness) can persist. Unless fluid warmers or appropriate low-viscosity fluids are used, performance may degrade.

- Maintenance Advantages — On the plus side, electric cranes sidestep many of diesel’s winter pitfalls. There’s no need for block heaters, DEF systems and there’s less cold-start battery stress. Electric motors also don’t require a complex emissions after¬treatment system.

- Operator Comfort — While diesel powered machines may require auxiliary heaters to warm operators and systems, electric cranes can direct energy to cab heating without the same idling penalties.

- Infrastructure Constraints — On cold jobsites electric cranes need power to recharge. If grid power is limited, operators may need to rely on diesel generators, which dilutes environmental gains. Cold charging also reduces battery efficiency.

Best Practices for Cold Weather Crane Operation

The following practices help maximize crane reliability and safety in winter — whether diesel or electric:

- Pre-warm and circulate. Before doing any lifts, circulate hydraulic fluid, warm engine compartments and ensure fluids are at operating viscosity. Use engine block heaters or hydraulic oil warmers as needed.

- Use the right fluids. Switch to low-temperature-rated hydraulic oils, lubricants and coolants. In diesel models, confirm that DEF systems are winterized (heated, insulated).

- Maintain thermal management systems. Inspect heaters, radiators and thermostats. Confirm that SCR systems for diesel cranes are properly warmed and functioning correctly before starting operations.

- Cold-climate training. Operators should be trained in winter-specific lifting protocols, including slow boom movements, cautious winch operation and constant monitoring for ice accumulation or stiffness in pulleys.

- Battery care (for electric cranes). Keep batteries warm, either with built-in heaters or external warming systems. Charge in a controlled environment where possible and avoid over-discharging in cold weather.

- Scheduled inspections. Increase the frequency of inspections on hydraulic lines, boom pins, sheaves and brakes because cold stresses can exacerbate wear and fatigue.

- Plan for recovery. Even with the best preparation, machinery can fail. Have contingency plans, snow-clearing gear and backup heating, power or auxiliary equipment ready.

Choosing the Right Crane for Winter

For operations in cold climates, the decision to deploy diesel or electric cranes depends on multiple factors. With smart planning and winterization practices, operators can safely navigate the trade-offs between traditional diesel power and emerging electric solutions without compromising lift capacity or uptime.