Crosby Upgrades Two Clamp Products

Enlarge Image

July 1, 2015 - Crosby has enhanced two of its clamp products: the IPU10A vertical lifting clamp and the IPSC10 screw clamp line.

Crosby IPU10A vertical lifting clamp

The IPU10A “automatic closing” clamp allows the user to properly attach the clamp to the top edge of steel in hard-to-reach applications, eliminating the need for ladders or other potentially unsafe devices. When the material is engaged fully into the top of the jaw, the clamp will automatically close and lock and the material can be moved. When the material is landed, the clamp can be locked open in the normal way allowing it to be removed and ready for the next lift.

The IPU10A is available in capacities of 1 and 2 metric tons with jaw openings available 0-.79-in./0-20mm and 0-1.38-in./0-35mm, respectively.

The clamp is RFID equipped as standard and includes a minimum WLL of 10%, 180 degree operation, material hardness up to 37Rc, universal eye, and 200% proof test with certifications and instruction manuals.

|

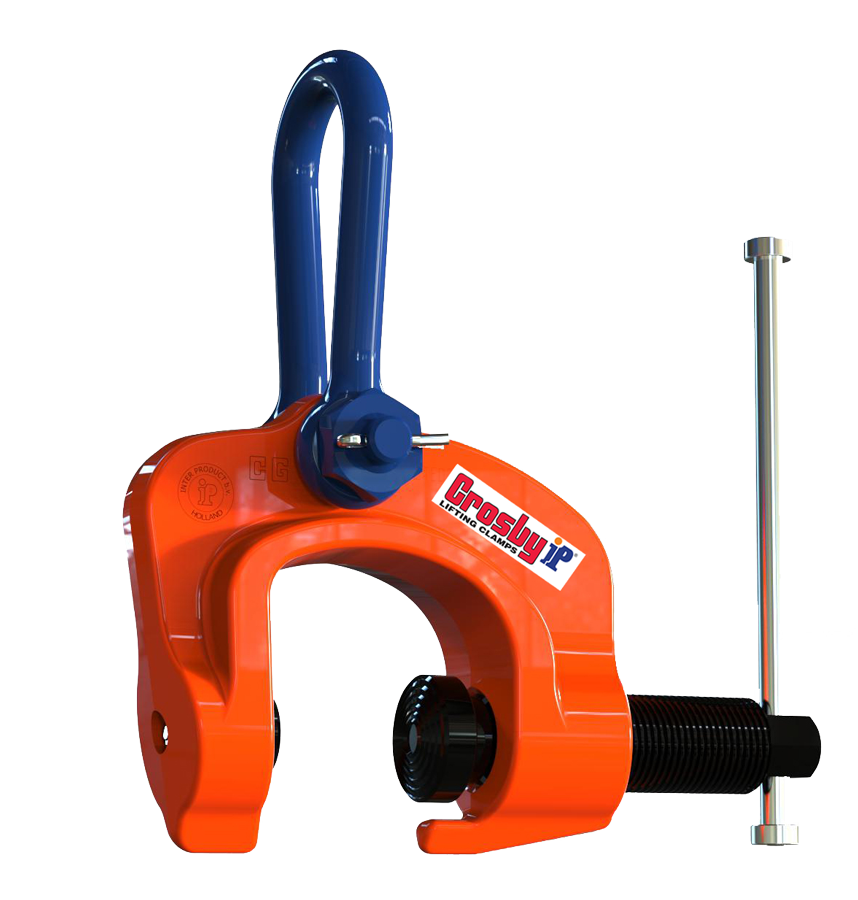

| Enlarge Image Crosby IPS10 screw clamp |

Crosby also enhanced its IPSC10 screw clamp line with a redesign that comprises larger jaw openings. It is the new forged alloy steel body design which allows for the larger jaw opening. Larger jaw openings are available for capacities of 1.5 and 3 metric tons with new jaw opening of 0-1.57-in./0-40mm and 0-2.36-in./0 - 60mm, respectively.

The IPSC10 is suitable for use in positioning and turning of steel plates or fabrications. The new design allows more material to be positioned or turned at one time saving time and creating more efficiency in the workplace.

The clamp is RFID equipped, suitable for steel with a surface hardness up to 30 Rc, and individually proof tested to twice the WLL with certification. Each product is individually serialized, with the serial number and proof load test date stamped on body.