Kate Lampson on Leading the Next Generation at Lampson International

Kate Lampson is the third generation of her family to work in Lampson International, the eminent crane service provider that has grown from a small crane and drayage company founded in 1946 by her grandfather and grandmother, Neil and Billie Jane Lampson.

Now led by Kate’s father, CEO Bill Lampson, Lampson International is still headquartered in Kennewick, Washington, with a major branch offices in Australia and Canada, and employees who work around the globe.

Currently, Kate is Lampson’s director of business development and marketing, while her brother, Peter, works in sales and operations.

Though Kate has officially worked at Lampson for a total of 22 years now, she has really been involved with the family business and the crane industry for almost all of her life.

Recently, she shared insights about her career, the company and the industry.

Q: What are your main responsibilities?

I oversee all of the company’s business development and marketing, including market research, trade shows, conferences and client relations, as well as its website, social media and advertising.

Q: What is your education and training?

After earning a degree in communications from the University of Colorado at Boulder, I immediately went to work for the family business.

Most of my training has come on the job, but also through some professional courses.

Q: How did you become interested in the business?

I knew that I wanted to work in the family business since I was five years old.

Whether I was riding through the yard with my dad on weekends to check the inventory, or listening to my grandparents discuss business at the dinner table or serving dinner to visiting customers, I’ve always had a passion for the family business.

My love for that business and the construction industry, as well as the many great friendships and business relationships that our company and family have cultivated over almost 80 years, keeps me passionately involved today.

Q: Can you give us a brief rundown of your career?

Fresh out of college, I spent six months working in many departments at our headquarters in Kennewick to learn about the overall business.

Within a year, I moved to Australia to work in our home office in that country.

During two years Down Under, I added experience both in the office and on jobsites all around that continent.

After that, I decided to challenge myself and broaden my experience by working for someone other than the family business.

I did that for four years before returning to Lampson, where I have worked for the past 19 years.

Q: What excites you most about the industry and your work?

The people. The whole industry has such a close-knit group of extremely good people working together, people I consider friends and who our family has done business with for decades.

I am also always amazed to see the new technologies emerging in the crane industry.

Whether its state-of-the art computer systems improving safety, creative design elements making equipment more accessible, versatile and efficient or aerial mapping technologies that report with pinpoint accuracy and help save customers time and money, I find it all very interesting.

Q: What about your work satisfies you most?

My many roles in business development, marketing, human resources and government affairs make every day different.

I might be in the field in a hard hat and boots giving a tour in the morning, working on an ad at my desk in the afternoon and representing the company at a dinner or reception in the evening.

The variety keeps the job fresh and interesting.

Q: What’s the best advice you’ve ever received?

A woman I served with in a volunteer organization expertly balanced a full-time job, volunteering and raising twin daughters.

She told me that everyone needs some help, and that we shouldn’t be afraid to ask for it. “Surround yourself with good people that you respect and that you trust to help you, and, in turn, that you will take care of,” she advised.

That wisdom continues to serve me well today.

Q: What are the industry’s greatest challenges, and their solutions?

Our biggest challenges today are high insurance rates, labor shortages and a saturated equipment market.

The solutions?

Regarding insurance, a company must do its best to protect its carrier, negotiate the best possible rates and premiums and work hard to keep its safety record clean and its OSHA recordables down.

As for labor shortages, I think the industry is doing a good job of addressing them.

Working with organizations such as the Specialized Crane & Rigging Association (SC&RA) and SC&RA Foundation, National Commission for the Certification of Crane Operators (NCCCO) and NCCCO Foundation, the Associated General Contractors (AGC), unions and the Future Farmers of America to promote our industry and recruit workers is a great start.

Working with local economic development councils, chambers of commerce and local and statewide non-profit organizations is a great additional step.

With regard to equipment availability, Lampson has for many years felt that the equipment market has had too many players and not enough projects to go around.

However, things appear to be looking up, thanks to the new federal administration’s support for the petrochemical and nuclear industries.

Q: What industry boards and committees do you serve on?

I am currently on the NCCCO Foundation’s board, and I just completed a three-year term on the SC&RA Crane and Rigging Governing Committee as well as the Crane and Rigging Task Force Committee.

Q: What do you do when you’re not working?

I enjoy hiking, traveling, playing tennis, trying new restaurants, wine tasting, spending time with friends and family and of course being home with my pets.

Q: What have been Lampson’s key milestones over the past five years?

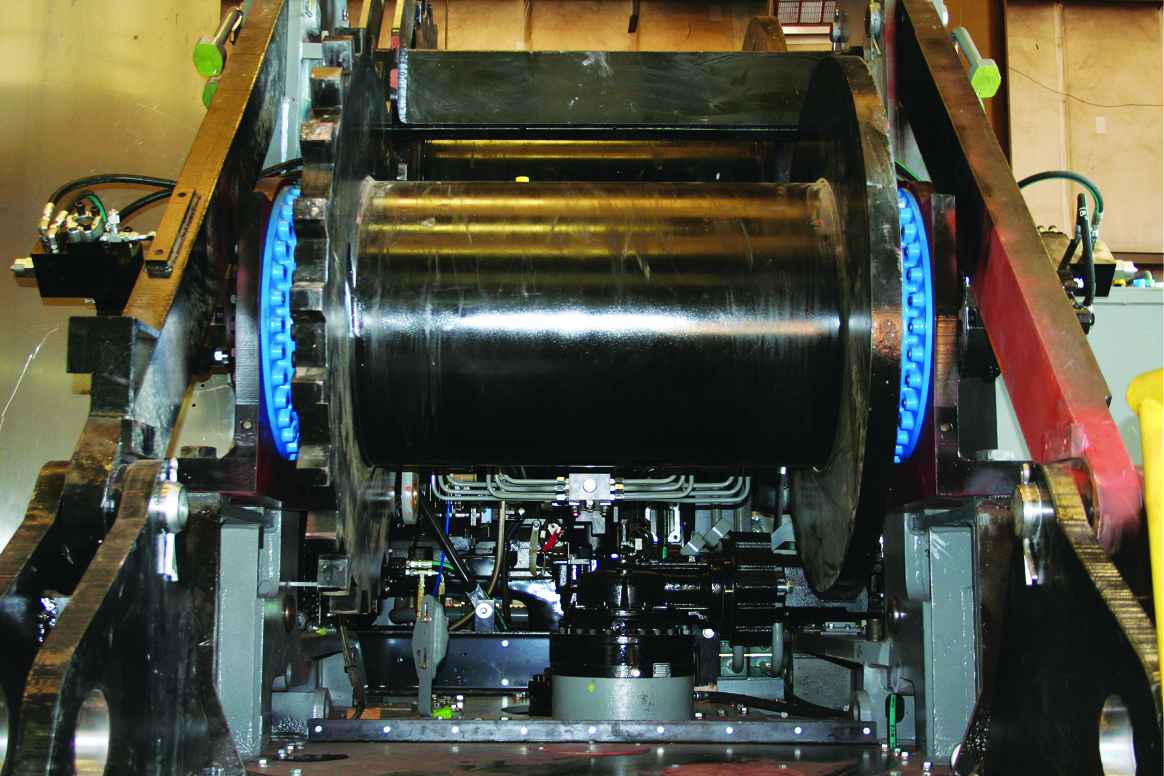

Our biggest milestone in that time has been the success of our Millennium Series of crawler cranes — structurally rugged Manitowoc model 4100, and 4600 Series-4 cranes that have been upgraded with modern power plants, controls and hoisting systems.

To date, we have produced 25 Lampson 4100 Millennium cranes. Many are working productively and reliably for rental customers, and 12 have been sold.

We have just committed to make another five, and three of them are pre-sold.

In addition to our 4100 models, we are now starting to convert our Manitowoc 4600 Series-4 cranes into Millennium units.

The Millennium cranes have been very well received across the industry and are most in demand in the marine services, infrastructure and industrial sectors.

The Millennium cranes have grown more popular in the past year, and we will produce them as long as we see demand.

Q: What has enabled Lampson to have so much long-term success?

Ever since my grandparents started the business almost eight decades ago, its philosophy has been to keep overhead low, do everything ourselves and never lose a customer.

That philosophy has served us well for three generations in the business, and it will continue to serve us well into the future.

Q: What are Lampson’s key business offerings?

Lampson International provides heavy lift and heavy haul services to the petrochemical, nuclear, industrial, commercial and marine industries.

We buy, sell, manufacture, rent and re-manufacture cranes as well as manufacture our proprietary products: the Lampson Crawler Transporter and the Lampson Transi-Lift mobile cranes.

We also have a fleet of self-propelled and towable specialized trailers made by Goldhofer, Scheuerle, Nicholas and Commetto. We use them in our own heavy haul services and also rent them to customers.

Besides heavy lift and heavy haul services, we provide customized engineering and rigging services, and use of our 850-ton pull-test system. We also operate the Columbia Pacific Transport trucking company.

Q: Do you foresee Lampson expanding to other continents?

We don’t currently plan to expand, but anything is possible with the right opportunity.

Q: Is Lampson developing any new products or services that you can tell readers about?

As a reltatively new service, we now can use our Horizontal Hydraulic Pull-Test System to verify the strentgh of customers’ rigging components in capacities to 850 U.S. tons and total lengths to 100 feet.

Q: With friction rigs still a Lampson mainstay, how do you find and train operators?

We are always looking for skilled labor and great operators to maintain and run our equipment.

We use many resources to find qualified workers.

From word of mouth to career fairs spanning grade schools to colleges as well as FFA events and trade schools, we are seeing an interest in the construction industry.

It is also great to see organizations like the SC&RA, NCCCO, National Center for Construction Education and Research (NCCER), the AGC and well as all of the trades actively engaging to help with recruitment efforts.

Bright Future

By coupling innovative offerings with a multi-generational commitment to doing the right thing for customers, employees and the lifting industry as a whole, Kate Lampson and her family are poised to keep Lampson International a leader for decades to come.