Link-Belt Introduces 248V Next-Generation 200-Ton Crawler Crane

Link-Belt’s new 248|V lattice-boom crawler crane is the fifth and newest generation in the 248 family of 200-ton lattice boom crawler cranes.

The V in the model name is a visual reminder that the new crane is the fifth generation of the 248, which originated in 1994 and has seen new generations rolled out in 1998, 2004, 2013 and now 2026.

The V in 248|V also shows that the crane’s power comes from an engine meeting the world’s toughest clean-air standard for offroad diesels — Europe’s Stage V.

That’s even a step cleaner than the current U.S. EPA Tier 4 Final standard.

The new 248|V combines the proven

strengths of its 248 HSL predecessor with powerful new features that streamline setup, simplify operation and boost productivity.

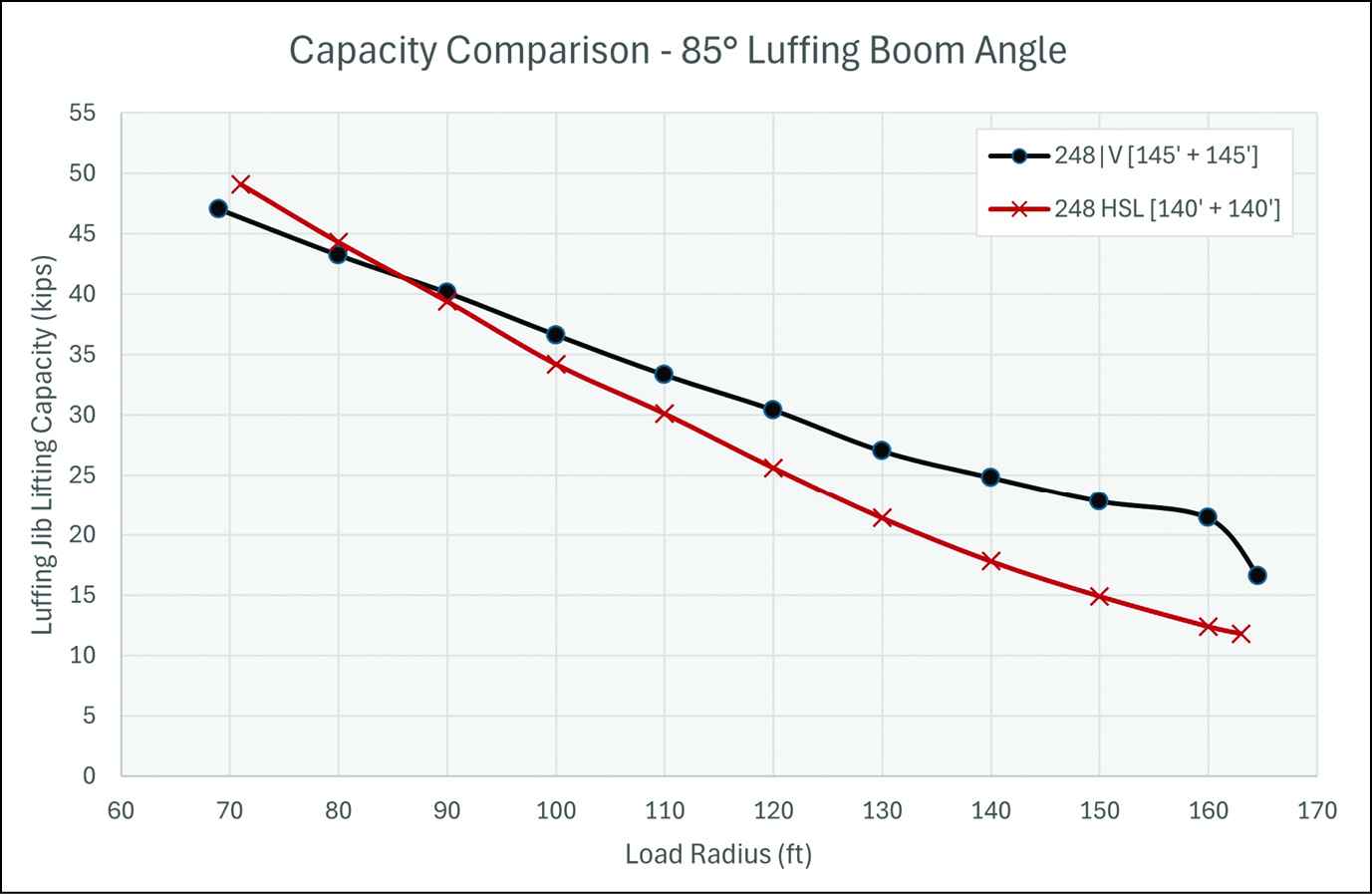

One of the most notable upgrades is a brand-new luffing jib that offers considerably more lifting capacity than the previous one while also being easier to transport and install.

Link-Belt will unveil the 248|V and the new luffing jib in booth F35029 at CONEXPO-CON/AGG 2026 in Las Vegas, Nev., March 3-7.

The company plans to start shipping the 248|V in the third quarter of this year.

New Benefits

The new 248|V’s expanded versatility, easier assembly, operator-friendly features and powerful new luffing jib will certainly draw strong interest from a wide range of crane users.

“200-ton capacity cranes are mainstays throughout the lifting industry,” said Michael Dawson, Link-Belt’s product manager for lattice- and telescopic-boom crawler cranes. “They erect structural steel, drive pile, set precast concrete, tilt up concrete panels, move heavy machinery, set rooftop HVAC equipment and do so many other jobs.”

He noted how that kind of versatility helps a crane stay busy by working on many kinds of jobs or by working on many phases of one long-term job.

Dawson added that users will find the new 248|V even more versatile than earlier versions, thanks to features like Link-Belt’s Combo boom top.

“That one boom top works with the new 60,000-pound capacity heavy-duty tip extension, the fixed jib, the new higher-capacity luffing jib and even pile leads,” Dawson said. “So you don’t have to stock and ship multiple special boom tops, and you can change attachments quickly and easily.”

To make boom and jib assembly, transportation and stowing even easier, the new boom and luffing jib are supported by bar pendants that store atop their corresponding boom sections.

Current 248 HSL owners who buy the new 248|V can retain their investment in existing boom, as the 248 HSL extensions can be upgraded and then used on both models.

In addition to the new boom and luffing jib, the 248|V also brings many other improvements that make setup and operation even better.

A few of them are a new upperworks counterweight that can be installed by remote control, a new Stage V-compliant diesel engine with auto idle start/stop, a new larger in-cab operator display, new standard cameras, new optional lighting package, new fall arrest anchors, easier access with the upperworks at any angle, a new larger third drum mounted in a boom extension, a boom base with Quick-Draw self assembly cylinder to streamline setup, a standard free-spool reeving winch to help luffing-jib rigging and an optional auxiliary generator to power the cab when the crane’s main diesel engine is stopped.

Here is a closer look at some of them.

Remote-Controlled Counterweight

The 248|V’s new upperworks counterweight offers convenience, both during installation and crane operation.

The lowerworks counterweight is still two 17,700-pound boxes attached manually to the carbody, same as on the previous model.

But the new upperworks counterweight on the 248|V can be fully installed by remote control from the ground or an upperworks catwalk.

That means no one ever needs to stand on a ladder during installation or removal.

A hydraulic cylinder raises the 11-piece, 141,720-pound upper counterweight assembly and hooks it onto the counterweight support frame.

An integrated assist rod helps pin and unpin the cylinder from the counterweight.

Once the counterweight is installed, sensors tell the crane’s computer how much counterweight is on the machine so that the control system can help the crane operator set up the counterweight configuration.

Also, the counterweight support frame has standard mounting lugs to support a piledriving power pack.

This feature offers a convenient place to mount a power pack where it will move with the upperworks and not take up ground space on a work site.

Comfortable High-Vis Cab, Operator-Friendly Controls

Every operator will notice the cab and control upgrades in the 248|V.

It uses the same cab introduced on the 218|V in 2023 and is similar to cabs used on Link-Belt’s newest lattice-boom crawler cranes.

That means operators will instantly feel comfortable and productive in it.

Dawson noted that the function levers on the 248|V are pilot-pressure controls with digital monitoring. “The pilot controls let an operator feel the load, while the digital monitoring gives excellent information and provides excellent control and a smooth ramp to stop auto functions. Dials in the cab let the operator customize function speed to his needs.,” he said.

The 248|V cab uses the same 12-inch touchscreen display as the 218|V, and the system gives a wealth of vital information.

For example, it can tell ground-bearing pressure, amount of counterweight, levelness, swing angle and diagnostics.

It can also log operating data and provide operator aids like work-area limits and function alarms with auto stop.

Dawson thinks operators will like the choice of engine throttles. The pedal throttle boosts engine power but not function speed. The hand twist throttle boosts both engine power and operating speed.

“For example, an operator may want the pedal-throttle’s high power and low speed when picking and carrying a load or traveling up and down a grade, but may prefer the twist-grip throttle’s high power plus speed for swinging or lifting on a long boom,” he said.

A comfort option that’s new on the 218|V and 248|V is an auxiliary power unit (APU) that uses a 10.5-horsepower diesel engine to power the cab’s HVAC and electrical systems when the crane’s main engine is turned off.

The crane operator can choose whether to use the APU, and can set it to coordinate with the main engine’s idle-off system.

“By keeping the cab operational while the main engine is off, the APU can keep the cab comfortable and operating while also reducing the number of hours logged on the main diesel,” said Dawson.

Third Drum In Boom Extension

The new boom for the 248|V offers a 10-foot section that can house an optional third drum that can be used for a whipline or for operating the luffing jib.

Putting that drum in a 10-foot boom section instead of the boom base makes it easier to ship the section with the luffing jib and to only install it on jobs where it will actually be needed.

Strong Capacities and Reach

Maybe the best thing about Link-Belt’s new 248|V is that is delivers so much new convenience while equaling or bettering the performance of its predecessor.

Lifting capacities and maximum lengths for the 248|V’s boom (285 feet) and main boom plus fixed jib (245 feet + 100 feet) are the same as or better than those for the 248 HSL.

However, the new heavy-duty tip extension for the 248|V with Combo boom top can handle 60,000 pounds, versus 40,000 pounds for the 248 HSL’s tip extension.

And the new luffing jib for the 248|V , which is based on the proven design of those for the 298 and 348 Series 2, shows impressive lifting capability, from its maximum capacity of 96,000 pounds at a 35-foot radius on 105 feet + 85 feet, to 3,800 pounds at a 250-foot radius on the maximum combination of 155 feet +185 feet.

Easy Transportation

The 248|V ships as economically as possible for a crane of its capacity.

The main shipping unit weighs just 90,500 pounds, including the carbody with hydraulic setup jacks and the upperworks complete with live mast, boom base and Quick-Draw self-assembly cylinder.

On a lowboy trailer with four inches of cribbing, that load sits under 13 feet 6 inches high and 11 feet wide.

All other loads weigh less than 41,500 pounds.

For example, a 248|V with full counterweight, 285 feet of boom and 100 feet of fixed jib can travel in just 11 total truckloads.

CONEXPO attendees can get a first look at the new Link-Belt 248|V with 145-foot boom, 145-foot luffing jib and luffing-jib upper point in booth F35029 in the Festival Grounds at CONEXPO in Las Vegas, March 3-7.