Link-Belt to Roll Out HTT-86110 Telescopic Truck Terrain Crane at Bauma

|

| Enlarge Image Link-Belt's 110-ton capacity HTT-86110 telescopic truck crane |

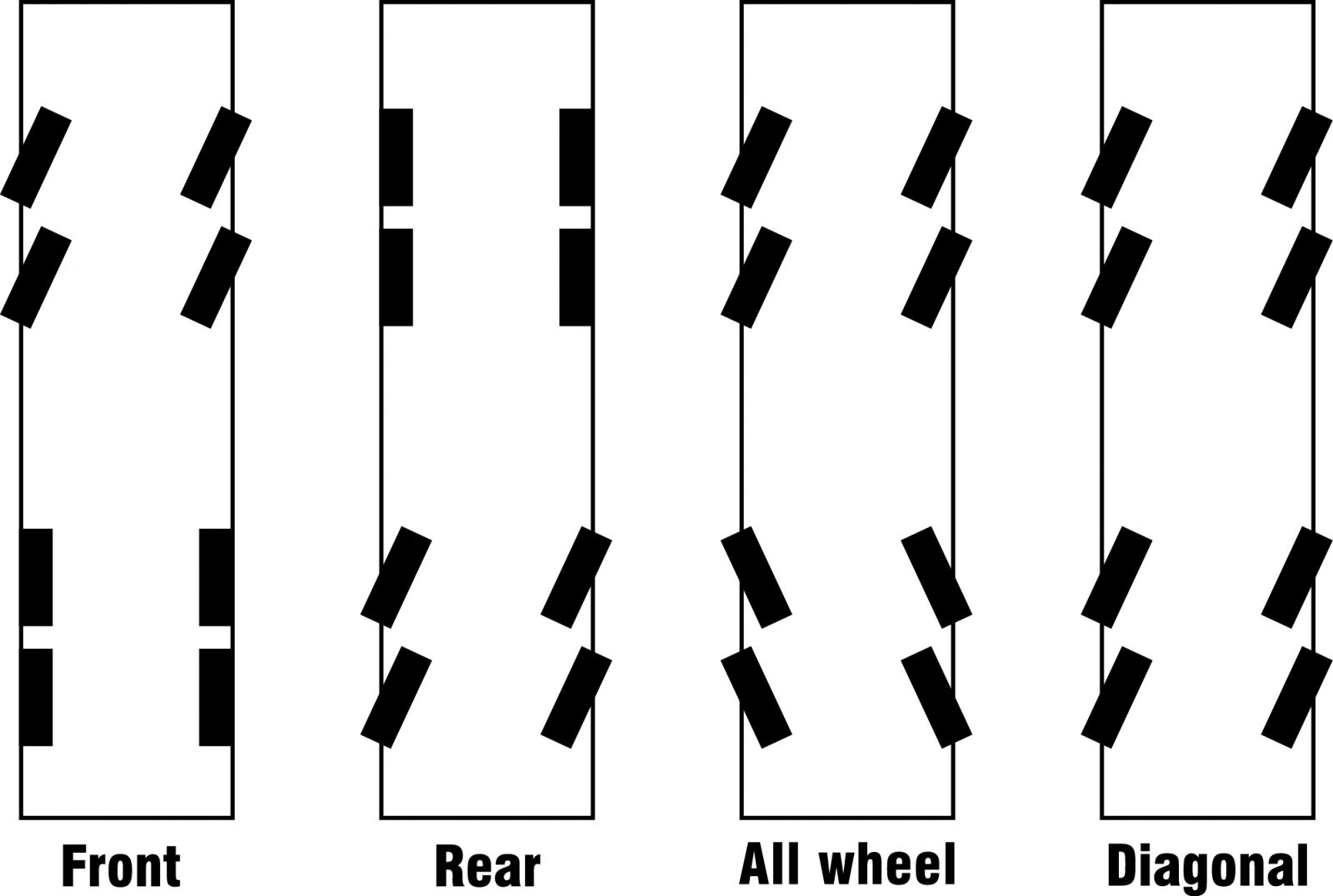

February 10, 2016 - Link-Belt Construction Equipment Co., Lexington, Ky., announced last week it will be debuting the 110-ton capacity Link-Belt HTT-86110 telescopic truck terrain crane. The unit features an all-wheel steer capability for maneuvering in congested spaces. Steerable rear axles with super single tires and four steering modes—independent front, independent rear, combination, and diagonal, allow the crane to move in and around the jobsite with ease. The HTT-86110’s turning radius is less than 27.25 ft. from the centerline of the tire, which is comparable or better than similar four-axle all-terrain cranes.

Performance

|

|

Enlarge Image

|

A 480-hp, Tier 3-compliant engine is available on the HTT-86110. For the North American market, a clean idle certified Cummins 336 kW (450hp) engine is also available. Both the international and North American market versions of the HTT-86110 come with 1,550 ft.-lbs. of torque, and the carrier and upper engines couple to a ZF AS-tronic automated transmission with 12 speeds forward and two reverse. The controls for this transmission are similar to an automatic (no clutch pedal) but have the performance of a manual with automated pump dis-engagement for on-highway travel and jobsite maneuver modes.

The winch package delivers a maximum line pull of 20,739 lbs. and can provide over 16,000 lbs. of line pull up to the fourth layer, ideal for 19 mm (3/4 in.) wire ropes that are line pull rated at 15,700 lbs. and higher. The maximum line speed on the winch is 495 ft./ min.

Boom and attachments

The HTT-86110 features a 164-ft. main boom. The main boom tip height is 172.6 ft. The telescoping sections of the six-section pin and latch boom ride on Link-Belt’s Teflon impregnated wear pads. All the sheaves and both pins of the hoist cylinder feature sealed bearings as well.

A 58 ft. on-board fly is available and features four offset positions of 0, 15, 30 and 45 degrees, and an innovative approach for erecting and stowing to minimize the number of times a ladder is needed. The fly also features an integrated 10-ft. fly that reeves up to fpur-parts of line and is capable of 24-tonlifts. The 10-ft. fly is ideal for applications where two load lines are necessary for lifting one load. Two additional 16 ft. lattice boom extensions bring the maximum tip height to 261.6 ft.

Operator safety and comfort

The HTT-86110's tilting operator cab adjusts from 0 to 20 degrees, and a pull-out “Cabwalk” provides easy entryor the operator. Electronic controls in the cab are available in single- or dual-axis configutrations and have a fine metering feature for precise operation. There is a designated foot pedal for boom telescope operation. The swing control allows the operator to free swing and use a foot pedal for smooth braking. Aiding the operator is the Link-Belt Pulse system with telematics, and cameras that automatically let you view winch operation and swing. Extra touches are heating, air-conditioning, and AM/FM radio with Bluetooth.

The driver’s cab features comprehensive gauges, tilt/telescoping steering wheel, and a clever place to store documents. Its fiberglass construction is Link-Belt proven and the interior is acoustically insulated. Cameras automatically let you view backing up and when making a right turn. Heating and air conditioning, AM/FM radio, cruise control, intermittent wiper with washer, and engine compression brake all comes as standard equipment.

A work lighting package is available and includes four (4) high intensity LED work lights mounted on top of the operator's cab, the right side of the superstructure facing forward, on the upper work platform, and on the left side of the superstructure facing out. Also available are single and dual boom floodlights, and remote control boom floodlights that work in conjunction with other floodlights options.

Easy moves

The front and rear axle groups of the HTT-86110 have a combined transport capacity of 98,450 lbs. at highways speeds in excess of 60mph – a fully equipped crane with 4,000 lbs. of the standard 16,000-lb. counterweight can be onboard and still be under the transport capacity. An additional 44,600 lbs. of counterweight brings the maximum counterweight to 48,600 lbs. With no counterweight, the HTT-86110 can travel under 24,250.9 lbs. per axle.

Other features of the HTT-86110 include the upper work platform with foldable guardrail, wind speed indicator, aviation obstruction marking light and flag, halogen daytime running headlights and LED lighting, illuminated compartments and controls for night-time operation, four-points of access to the carrier, and ABS drum brakes.