Truck Cranes Meet Customers’ Needs for On-Road Mobility and Jobsite Lifting Performance

Truck cranes have been mainstays in the North American lifting industry for nearly eight decades.

The first ones manufactured in the United States with purpose-built carriers may have come as early as the 1940s.

Now, 80 years later, truck cranes drive daily across the U.S. and Canada to pick and place everything from HVAC units to swimming pools and structural steel.

They are prominent in taxi crane service, where their ability to travel at highway speeds then set up quickly and make the needed lifts before heading off to the next job make them a perfect fit.

Andrew Soper, product marketing manager at Link-Belt, estimates that about 80 percent of truck cranes in North America are engaged in taxi crane work, though they are also particularly popular with steel erectors, and are involved in many other sectors of the lifting industry.

What is a Truck Crane?

Although some people in the industry call any crane that can travel on public roads a “truck crane,” there are really three distinct varieties of roadable cranes: truck cranes, all-terrain cranes and boom trucks.

Here’s what defines each type.

“A truck crane uses a purpose-designed carrier engineered specifically for a particular crane model,” said Mark Hooper, vice president, North American sales and Grove Defense at Manitowoc. “It integrates the superstructure, outriggers, counterweight system and controls into a single chassis optimized for lifting and travel at normal highway speeds.”

The major difference between a truck crane and an all-terrain crane, which may sometimes look similar, is their undercarriages.

“Truck cranes are built to travel on roads, so they have a simplified undercarriage and driveline design that is similar to a conventional chassis,” said Lance Rydbom, vice president of product management and engineering at Tadano America. “All-terrain cranes are built to travel both on and off of roads, so they have hydro-pneumatic suspensions.”

Manitowoc’s Hooper added, “All-terrains also feature multi-axle steering, larger tires and, often, longer booms and higher capacities. Their cost reflects their broader range of terrain capability.”

As Tadano’s Rydbom put it, “Truck cranes are a more economical option for customers who don’t need an all-terrain’s offroad capability.”

Indeed, whereas truck cranes typically have three or four axles and capacities from 40 to 120 tons, all-terrain cranes can have two to nine axles and capacities from 40 to 1,500 tons.

As for the distinction between truck cranes and boom trucks, the key difference once again is in the chassis.

“Boom trucks mount a crane onto a commercial truck chassis, for example a Kenworth or Peterbilt,” said Link-Belt’s Soper. “You could use that same commercial chassis for other vocational truck applications.”

Boom trucks typically have from two to six axles and capacities ranging from a few tons up to 80 tons.

Three Manufacturers

Three manufacturers sell truck cranes in North America: Grove, a division of Manitowoc; Link-Belt; and Tadano.

Together, they currently offer 19 models with capacities from 40 to 120 tons, main-boom heights from 102 to 205 feet, and maximum jib-tip heights from 128 to 263 feet.

The chart below shows the full range of models available in North America.

Grove models that begin with TTS and Link-Belt models that begin in HTT or end in TT feature steerable rear wheels.

All the others and both Tadano models steer only with their front wheels.

Key Features

All three of the experts we spoke with named the same key features that customers look for in truck cranes: highway travel speed, quick and easy setup and takedown, long booms, strong lifting capacity, maneuverability, minimum crew, operator comfort and, of course, reliability.

One expert noted that when it comes to lifting performance, truck crane customers are especially interested in reach and capacity on the main boom, since it lets them do more work without having to spend time deploying and later stowing a jib.

State of the Market

Link-Belt’s Soper says the market for truck cranes is “pretty good” right now, with demand being driven by fleet replacement.

“The average age of working truck cranes is relatively high, so many owners are refreshing their fleets. Also, it helps that overall construction activity is up,” he said.

Grove’s Hooper sees the market in a holding pattern right now, but he notes that crane rental houses remain busy and that long-term drivers like public infrastructure programs, utility work and data center construction remain strong.

Coming Developments

What new products and features can truck crane customers look forward to seeing in the not-too-distant future?

Hooper said Manitowoc continues to invest in control system advancements, telematics and operator comfort across the Grove truck crane range.

He added that the company is also working to improve travel efficiency and safety, and to align production schedules closely with market demand.

Hooper also noted that Manitowoc is expanding aftermarket support with new tools such as ServiceMax for asset tracking.

As for Tadano, Rydbom said the company is incorporating two years of customer requests and suggestions to improve its GT 800XL-2 and GT 1200XL-2 truck cranes, both rolled out in 2023.

Link-Belt’s Soper said the Lexington, Kentucky, manufacturer is now developing “some new truck cranes,” though he could not reveal details right now.

He also said Link-Belt will be adding even more user-friendly features, such as variable-position outriggers, to its truck cranes.

In addition, Soper noted that Link-Belt is revising its truck-crane and all-terrain drivelines to match the new internal combustion engines needed to meet tighter Environmental Protection Agency emission standards that start in 2027.

“Engine manufacturers are developing new platforms to meet the stricter standards, and we’re making sure our drivelines match up well with them,” Soper said.

Owners’ Insights

Alamo Crane Service Inc. is a family-owned crane, rigging, transportation and consulting company that serves clients throughout Texas from its headquarters in Selma, near San Antonio.

Founded in 1979 by husband and wife Marvin and Marge Ohlenbusch, who still lead the company today, Alamo has 65 employees and prides itself on its expertise, award-winning safety record, breadth of services and commitment to answering every call, day or night, 365 days a year.

The company’s cranes range in capacity from 15 to 770 tons and include boom trucks, truck cranes and all-terrains.

Most of Alamo’s truck cranes are involved in taxi-crane service, and each has an assigned operator.

The truck cranes with capacities from 40 to 60 tons often do many jobs per day, while the 80- to 120-ton units typically do just one or two.

“Our cranes lift whatever a customer needs picked and set,” said Marvin Ohlenbusch, “whether it’s an HVAC unit, compressor, swimming pool, structural steel or a railroad caboose.”

The top three things Alamo looks for when shopping for a truck crane are lifting capacity, boom length and reliability, said Marvin Ohlenbusch.

“Each of our operators has a set of additional features that they find most important, but they all agree that mobility and easy maneuvering are number one,” he added.

Other features high on Alamo operators’ lists are self-removing counterweights, hydraulic swing cabs and air suspension.

Marvin Ohlenbusch said that the recent truck crane developments that Alamo finds most interesting are variable-position outriggers, advancements in telematics and the overall computerization of the equipment.

“All of those advancements make operation and maintenance, easier, safer and more efficient,” he added.

The All Family of Companies is the largest privately-owned crane rental and sales business in North America.

Its more than 3,600 pieces of lifting equipment range in capacity from 3.1 to 1,200 tons.

That impressive inventory includes a fleet of truck cranes with maximum capacities from 40 to 115 tons.

Brian Meek, project manager, said truck cranes have relatively low axle loads, travel well on highways and can cover long distances, which makes them great for jobs with those requirements.

He added that truck cranes’ fast setup and take down make them excellent for doing multiple jobs in a day.

Most of All’s truck cranes need a permit to travel on public roads, he said, but the manufacturers’ success at minimizing axle loads makes permits easy to get.

Meek added that truck cranes work best on jobsites with flat, smooth, hard terrain, such as parking lots or construction sites that have firm, level ground.

He noted that although truck cranes with capacities in the 40- to 60-ton range now see competition from boom trucks, each type of crane has advantages.

“Although boom trucks often have longer booms,” Meek said, “truck cranes usually have more lifting capacity.”

In general, All’s operators move from rig to rig to meet the flow of work.

“Fortunately, truck crane manufacturers have made their products somewhat similar,” said Meek, “so it’s easy for an operator to be comfortable in any brand.”

All’s top three factors when evaluating a truck crane are axle loads, boom length and lifting capacity, said Meek.

What new developments in truck cranes does All find most exciting?

“A few manufacturers are incorporating European-style superstructures onto their North American carriers, reminiscent of an all-terrain crane,” said Meek. “We are intrigued by the possibilities.”

He explained that a European-style upperworks emphasizes compactness, light weight, using one carrier-mounted engine to power both travel and crane operation (instead of having separate engines for the carrier and crane) and more flexibility in positioning axles to meet roading regulations.

“It’s encouraging to see truck crane manufacturers continue to invest heavily in this market,” said Meek. “Reliable truck cranes will always be in demand.”

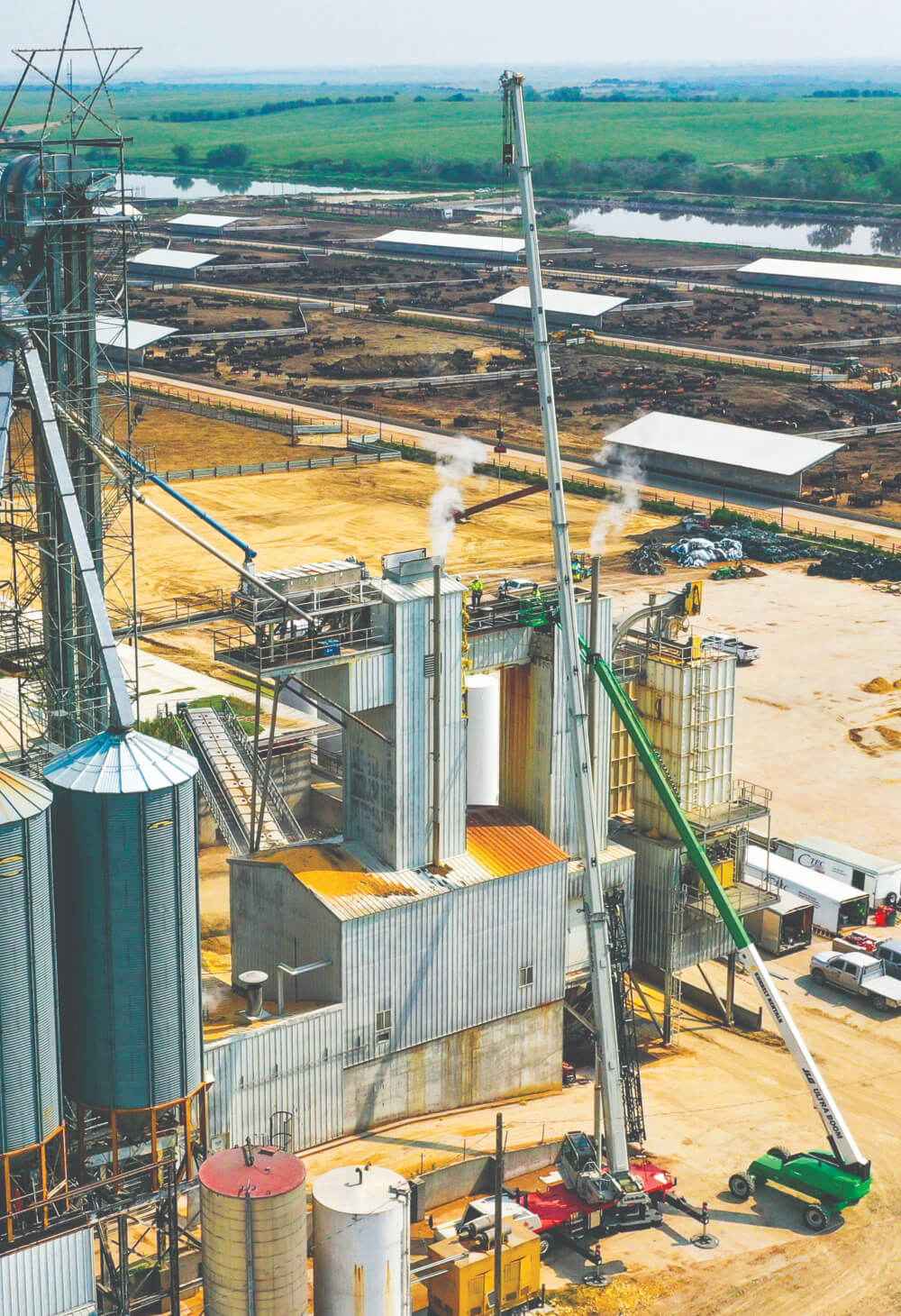

He added that they are ideal for steel erection, general construction, HVAC work and agricultural applications.

“That’s why truck cranes will always have a place in the All fleet,” Meek said.