Once considered niche machines, noted Michael Dawson, product manager of crawler cranes at Link-Belt, the extreme versatility of teleboom crawlers has led to more contractors, crane rental houses and owners finding value in their use.

“The telecrawler market is steady and trending upward with modest growth,” Dawson said. “This is noteworthy, because as the economy grows stronger and the U.S. infrastructure is progressively rebuilt, they are sure to be put to work on more jobs.”

With 2024 being an election year, we saw a little drop off in the teleboom crawler market, related Allen Kadow, product manager, telescopic and lattice boom crawler cranes at Tadano. “But the telecrawler market appears to be on the rise in 2025,” he said.

“We are seeing some of the funding for the infrastructure bill just now being disbursed and that will stimulate growth,” Kadow explained further. “Also, as the tariff situation may temper some projects, as it settles and they become final we believe we will see the market trend upward.”

JJ Grace, product manager at Grove, pointed out that increasing demand for larger capacity models is driving strong growth in the over 100-ton telescopic crawler crane market.

“Infrastructure investment continues with major bridge, highway and rail projects fueling this trend,” Grace said. “At the same time, the renewable energy sector is emerging as a key growth area where wind turbine installation and maintenance require cranes capable of handling heavy components at significant heights, and as support cranes for large lattice crawlers.

“These sectors continue shaping a robust outlook for higher capacity telescopic crawler cranes,” Grace added. “Contractors are increasingly seeking machines that offer reach, pick and carry and increased lifting capacities.”

There are a diverse number of tele-crawler applications, including wind, road and bridge, petrochemical, tilt wall construction and more, pointed out Brian Peretin, general manager – sales in the Mobile and Crawler Cranes Division of Liebherr USA, Co. “We see a strong push in multiple markets within the U.S., including green energy, infrastructure, data centers and distribution centers,” he said.

“Within these sectors demand for teleboom crawlers continues to grow,” Peretin continued. “That’s because of the increasing need for more flexible, compact machines with strong charts and easy transport capabilities.”

Latest Technologies

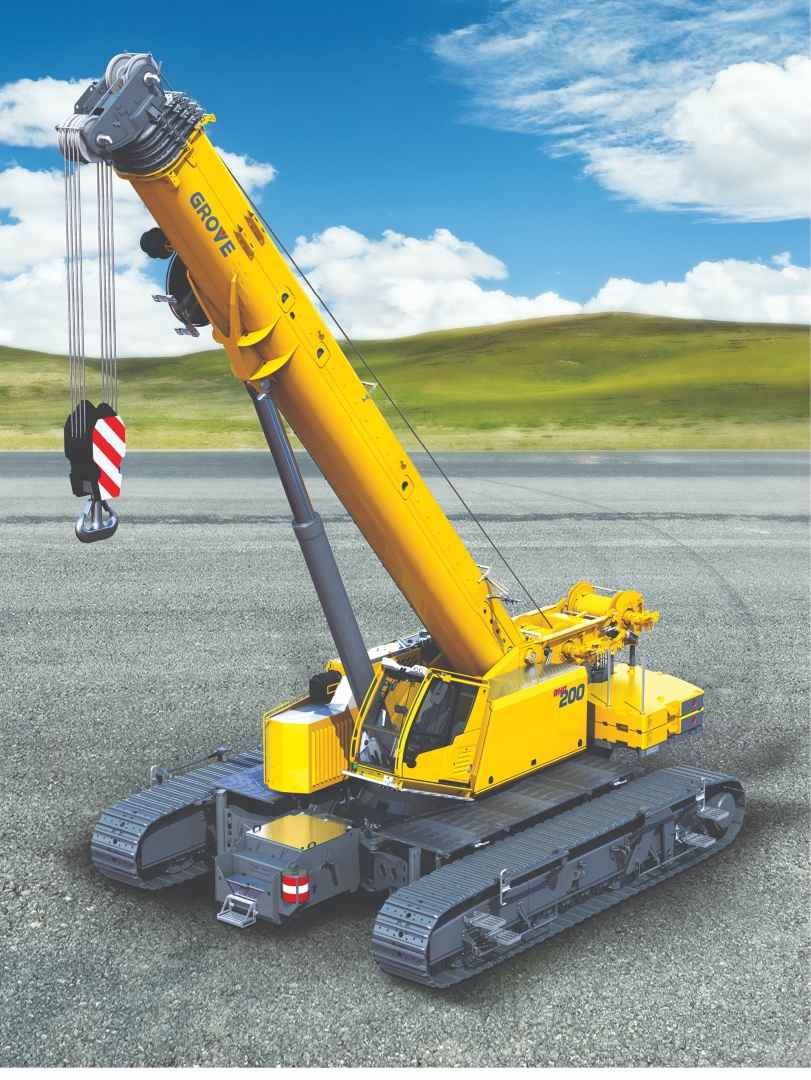

Grove’s new GHC200 telescoping crawler crane is the manufacturer’s highest capacity model, related JJ Grace. It offers 200 tons of lifting capacity with a 185-foot main boom and features a 90% pinning location on the boom for added setup flexibility, a tip height of up to 265.7 feet with extensions, and full pick-and-carry ability on inclines up to 4°.

“The GHC 200 was designed to deliver powerful lifting performance on challenging jobsites, including swampy or mountainous terrain,” Grace stated, “and for demanding applications in general construction and renewable energy. It is also engineered for transport efficiency with six to seven truckloads and fast self-assembly. Additionally, operators benefit from a tilting cab, climate control, enhanced visibility with multiple cameras, and improved ergonomics aimed at increasing comfort and productivity.”

The transition to Stage V engines in Link-Belt telecrawler cranes addresses sustainability concerns, related Michael Dawson. “Along with that, one of our guiding philosophies is to over spec our undercarriage components to provide for a longer service life and dramatically lower ownership costs,” he added.

“We continue to innovate for day-to-day performance with the latest Rated Capacity Limiter (RCL) system in our teleboom crawler cranes,” Dawson continued. “That offers operators a user-friendly interface common to other Link-Belt products along with various features unique to telecrawlers. Those include ground bearing pressure information, list charts, joystick-operational travel and function kick out for establishing lifting parameters, and for meeting other customer needs.”

Most of the improvements you will find on Tadano GTC teleboom crawler cranes, according to Allen Kadow, are in the form of tweaking already proven and reliable systems for efficiency, controllability, maintainability and rapid deployment of the machines. “The addition of optional third winches and power-pack mounting frames have also improved efficiency,” he added.

Liebherr has expanded its range of telescopic crawler cranes with their new LTR 1150 model. The crane, positioned between the LTR 1100 and the LTR 1220, offers around 50 percent more lifting capacity than the LTR 1100. It has a 170-ton maximum load capacity with a 171-foot telescopic boom, and a hoist height of 272 feet and a maximum radius of 249 feet. The crane is available with a maximum track width of 19 feet, a reduced width of 16.4 feet and a narrow 11.5-foot track width.

The LTR 1150 is the first of the manufacturer’s telescopic crawler cranes to be equipped with the Liebherr VarioBase, which determines the optimum load capacity in real time depending on the fixed track width and the variable rotation angle, Peretin noted. “The variable supporting base not only provides greater safety for the telescopic mobile crane, but also allows for significantly higher load capacities, especially for lifts directly over the supports,” he explained further. “The advantage in terms of load capacity is achieved when performing lifts over the corners of the tracks, especially with reduced track widths.”

The LTR 1150 can also be transported as easily and economically as its sibling with or without crawler carriers. Included is an option for removing the carriers to reduce the crane’s transport weight. The variant requires a jack-up erection support consisting of four swiveling cylinders that support the crane on the ground while the tracks are removed and the low-loader positions itself under the crane. The two crawler carriers can be transported together on a standard semi-trailer by folding their integrated access steps.

For the first time for Liebherr telescopic crawler cranes, Peretin related, the company has calculated WindSpeed Load Charts for the new LTR 1150. “As with the other Liebherr LTR cranes, the LTR 1150 is also equipped with load charts for slopes up to a maximum of 4°,” he explained. “Now we’ve made it possible to work safely and flexibly at higher permissible wind speeds, even with the full load capacity in many boom positions.”

Proving Indispensable

“Telescopic crawler cranes are proving indispensable across a wide range of industries thanks to their compact size, quick setup and exceptional versatility,” said Grove’s JJ Grace. “Their ease of transport and adaptability also make them a popular choice in general rental fleets where flexibility and efficiency are key.

“In construction, telescopic crawler cranes are ideal for tight jobsites and are frequently used to lift steel beams, HVAC units and precast concrete,” Grace continued. “Infrastructure projects benefit from their pick and carry capabilities in bridge construction, highway overpasses, rail systems and utility installations such as power lines and pipelines.

“In the energy sector, these cranes support wind turbine assembly, solar farm construction and operations in oil and gas facilities,” Grace added. “Additionally, industrial facilities rely on them for equipment installation, relocation and ongoing maintenance in refineries and chemical plants.”

Allen Kadow at Tadano pointed out that the versatility of telecrawlers makes them ideal for performing foundation, bridge and heavy civil, wind support, powerline construction and maintenance and commercial construction jobs. “We recently developed a pedestal-mounted unit for a customer who needed to get powerline work completed in marsh environments,” he said. “Our engineering staff worked with the customer to mount the units on their pontoon crawlers and allowed them to get the cranes to where the work needs to be done.”

The highest volume of telecrawler jobs, noted Michael Dawson at Link-Belt, are applications requiring both enhanced mobility — for example, when a crane that can set up and work on both sides of a bridge in the same day is needed — and high lifting capacities where traveling with a load is required. The most common applications are infrastructure based, including road, rail and bridge work as well as for water treatment, transportation and various other general construction activities.

“As for unique applications, telecrawlers are truly fantastic machines, going where no other crane can,” Dawson added. “It’s not unusual to see them operate and tandem pick in extremely tight quarters, and they’re well known for their efficiency and versatility. With the demands of strict build schedules and budgets, the ability of telecrawlers to work fast and effectively no matter the jobsite conditions prove their advantage in any fleet.”